330 ml Ceramic sublimation mug A (white)

| Price included VAT

White, classic ceramic mug, well coated and ready for sublimation printing with a mug press. This sublimation mug is extremely popular because of the low cost and good quality. Best for small orders especially for holiday give away gifts.

Important!

- For efficient packing and to minimize the risk of damage during delivery, we recommend ordering ceramic mugs in sets of 12, 24, or a box of 36 pieces. You can mix different colored mugs in your order.

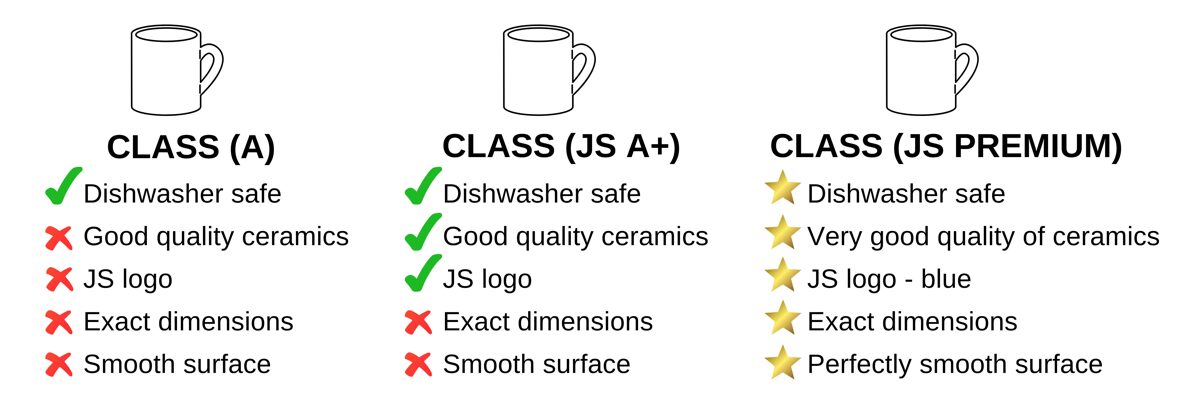

MUG QUALITY COMPARISON

Sublimating on white ceramic mugs offers three key benefits:

- The white background makes your designs look super bright and colorful.

- White mugs are like blank pages, so you can put any design you want on them.

- When you sublimate, your designs get stuck onto the mug, so they won't scratch off easily and will stay looking good for a long time.

Individual mug

- Capacity: 330 ml

- Height: 9,5 cm

- Diameter: 8,2 cm

- Material: ceramic

- Color: white

Wholesale

- Packing: 36 pcs

- Package weight: 13,5 kg

- Measurement: 410x270x310 mm

WHOLESALE SPECIAL PRICE

- For orders over 300 EUR, an additional 2% discount by entering the 2FROM300 discount code.

- For orders over 500 EUR, an additional 5% discount by entering the 5FROM500 discount code.

PRINTING TECHNOLOGY STEP-BY-STEP PROCESS

1. Design Preparation:

- Create or choose a design. Remember, sublimation works best with high-resolution images.

- Mirror the image using your design software (if needed), especially if there's text or the design requires a specific orientation.

2. Printing:

- Load sublimation paper into your printer.

- Print the mirrored design onto the sublimation paper using the sublimation printer and ink.

3. Preparing the Mug:

- Ensure the ceramic mug is clean and free from dust or oils. Wipe it with a lint-free cloth if necessary.

4. Securing the Design:

- Wrap the sublimation paper around the mug with the printed side facing inwards against the mug surface.

- Use heat-resistant tape to secure the paper in place. Ensure it's tightly wrapped to avoid blurring during transfer.

5. Using the Heat Press:

- Preheat your mug heat press according to the manufacturer's instructions.

- Place the mug into the press with the wrapped design facing the heat plate.

- Apply the recommended time, temperature, and pressure settings. Typically, this is around 180°C (sometimes 150°C) for 120-180 seconds, with strong pressure.

6. Transferring the Design:

- Once the timer goes off, carefully remove the mug from the heat press using heat-resistant gloves.

- Remove the sublimation paper and tape from the mug. Be cautious as the mug will be hot.

- Allow the mug to cool down completely before handling or packaging.

7. Final Steps:

- Inspect the transferred design for quality and vibrancy.

- If needed, wipe the mug gently with a soft cloth to remove any residue.

Tips for Success:

- Quality Materials: Use high-quality sublimation paper, ink, and coated mugs for best results.

- Temperature and Pressure: Follow the manufacturer's guidelines for your heat press to ensure proper sublimation.

- Handling: Use caution when handling hot items and allow them to cool before inspecting or handling further.

- If yellow edges remain during heating, it means that you are heating for too long.

- How long it should be heated can be influenced by also how new is your press.

By following these steps and tips, you can successfully sublimate designs onto ceramic mugs, creating personalized and professional-quality products.

Related products

Customer reviews

★★★★★

2 reviews

★★★★★

Ave M., 26 Feb, 2025

Väga hea kvaliteediga tassid.

★★★★★

Solvita R., 7 Jun, 2024

Laba kvalitāte!

Cart

Cart is empty.